Customs Clearance Tips for Automotive Parts Importers

by CR Express Team, Logistics Team • 16 min read

Customs Clearance Tips for Automotive Parts Importers

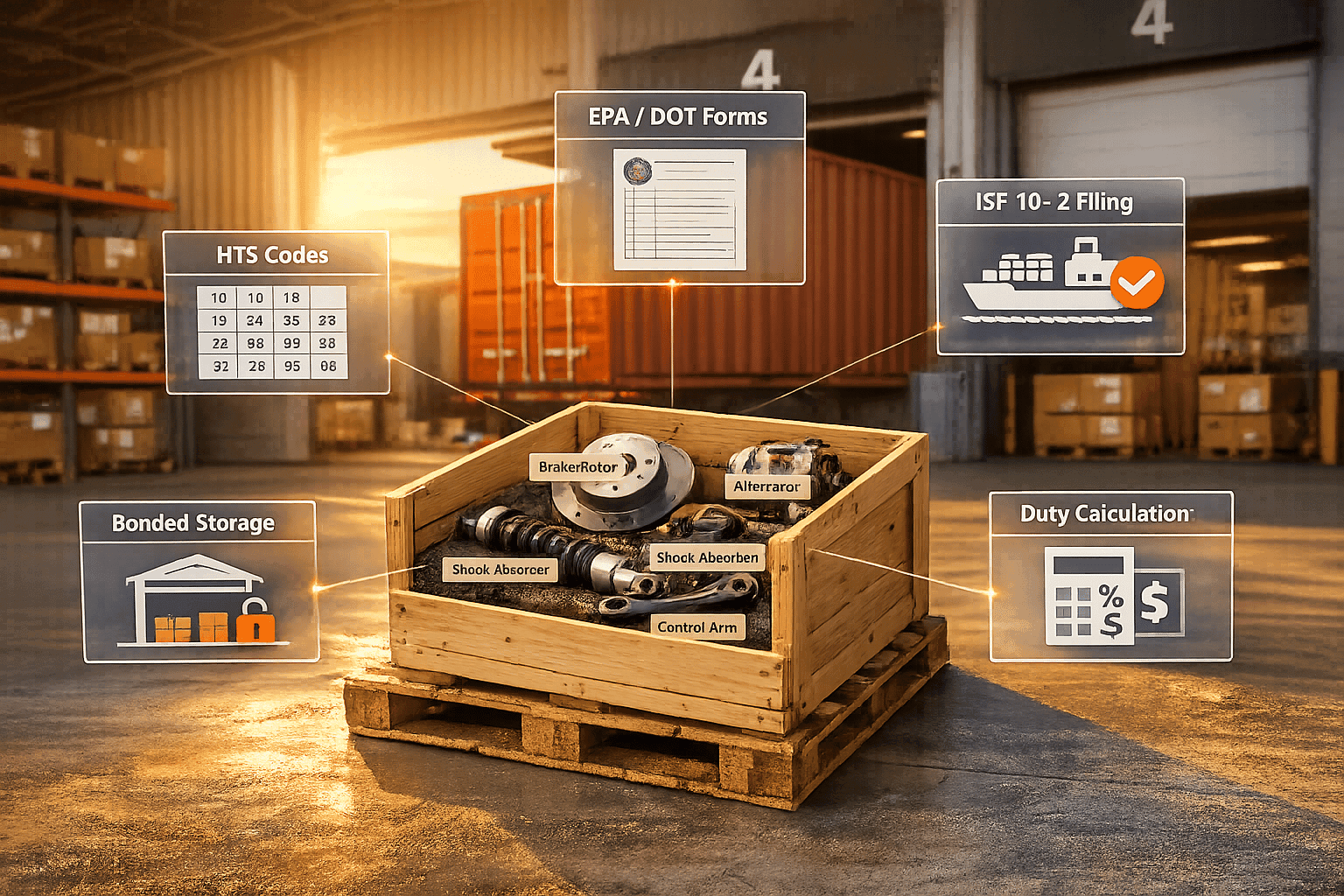

Navigating customs for automotive parts can be tricky, but it doesn’t have to be stressful. Here’s what you need to know:

- Paperwork matters: Over 30% of imports face delays due to incomplete forms or misclassification. Use precise HTS codes and submit proper documentation like commercial invoices, EPA Form 3520-1 (for emissions), and DOT HS-7 (for safety-critical parts).

- Tariffs can add up: Most auto parts have a 2.5% duty rate, but additional tariffs (like the 25% Section 232 tariff introduced in May 2025) can significantly increase costs.

- Plan for compliance: Ensure parts meet EPA and DOT standards, including emissions labels and DOT markings. Missing details can lead to holds or fines.

- Use bonded warehouses: Defer duty payments and improve cash flow by storing parts until they’re ready for the domestic market.

- Avoid intellectual property issues: Verify that parts don’t infringe on trademarks or patents to prevent seizures or penalties.

- Work with experts: Licensed customs brokers and logistics providers can help with classification, bonded storage, and duty relief programs.

Key takeaway: Accuracy and preparation are your best tools to avoid delays, fines, or unnecessary costs when importing automotive parts.

10-Step Customs Clearance Process for Automotive Parts Importers

Importing Automotive Parts from Mexico: A Comprehensive Guide

sbb-itb-c0b8770

1. Use the Correct HTS Codes for Product Classification

The Harmonized Tariff Schedule (HTS) code is a standardized numerical system used by U.S. Customs and Border Protection to classify imported goods. For automotive parts, most relevant codes fall under Chapter 87, though additional duties might apply under Chapter 99. Getting the classification right is key - it determines your duty rate.

Different rates apply to parts for passenger vehicles versus trucks. On top of that, tariffs from Section 301 and Section 232 could come into play. Misclassifying goods can result in costly penalties and delays.

"Mislabeling them with a general 'auto parts' description doesn't cut it." - Zarach Logistics

Avoid vague terms like "car parts." Be specific - list exact components, such as "ceramic brake pads", to ensure accuracy.

Automotive components are generally classified into six main categories in the HTS:

- Bodies and parts (e.g., windshields, seat components)

- Chassis and drivetrain (e.g., brake systems, gearboxes)

- Electrical components (e.g., spark plugs, fans)

- Engines and parts (e.g., gaskets, fuel pumps)

- Tires and tubes

- Miscellaneous parts (e.g., mufflers, radiators)

Getting the classification right here can smooth out customs processing later on.

When supplier details or product specifications change, audit your top-selling SKUs to ensure everything is still accurate. For parts imported from Mexico or Canada, apply the correct codes (like 9903.94.06) to benefit from USMCA preferential treatment. For particularly complex components, consider seeking a binding ruling or consulting an expert. For more detailed guidance, the U.S. Customs and Border Protection Informed Compliance Publication on vehicles, parts, and accessories is an excellent resource.

2. Complete EPA Form 3520-1 for Emissions-Related Parts

To ensure smooth customs clearance, it's essential to properly complete EPA Form 3520-1.

This form is used to confirm that imported engines and emissions-related parts meet Clean Air Act standards. It applies to all types of engines brought into the U.S. and acts as a legal declaration of the emissions rules, exemptions, or exclusions under which the engine is being imported. Components like catalytic converters, ECUs, and O₂ sensors may also need documentation to prove compliance. Additionally, engines must have an English-language emissions label. If the label is missing, you'll need to provide proof that the engine qualifies for an exemption.

Submitting the form electronically through the ACE system can help avoid delays in customs processing. For engines that don't meet compliance standards, you’ll need to work with an Independent Commercial Importer (ICI) to modify, test, and certify them. It's also important to check if your destination state - such as California, New York, or Pennsylvania - follows stricter California Air Resources Board (CARB) standards, which may differ from federal EPA requirements.

If you’re temporarily importing noncompliant engines for purposes like racing, testing, or display, you’ll need pre-approval from the EPA before shipping. Without this, you risk costly returns or other issues.

Accurately completing EPA Form 3520-1 is a critical step to ensure a hassle-free customs process.

3. Submit DOT HS-7 Form for Safety-Critical Components

The DOT HS-7 form is your declaration that imported automotive parts comply with Federal Motor Vehicle Safety Standards (FMVSS). This document is essential and must be submitted to both U.S. Customs and Border Protection (CBP) and the National Highway Traffic Safety Administration (NHTSA). Skipping this step could result in your shipment being rejected or even seized.

"If you're importing car parts that affect the vehicle's safety features (such as braking systems, lighting, and tires), you'll likely need to submit an HS-7 form at customs." - Dylan Sommer, ClearitUSA

This form applies to safety-critical components like brake pads, rotors, hydraulic hoses, shock absorbers, ball joints, headlights, tail lights, seat belt assemblies, tires, wheels, and automotive glass. These parts must meet the FMVSS standards in effect at the time of their manufacture. Look for a "DOT" symbol on the part or its packaging - this is a strong indicator that the item complies with U.S. regulations.

If the parts don't meet FMVSS standards, you'll need to work with a DOT-registered importer (RI) who can modify and certify them. Additionally, you'll need to post a DOT bond equivalent to 1.5 times the dutiable value of the parts, along with the CBP bond. For motor vehicles under 25 years old, compliance with all FMVSS is generally required for permanent import into the U.S..

Be as specific as possible when describing the parts you're importing. For instance, use terms like "steel brake rotors" or "LED headlamp assemblies" to avoid unnecessary delays. If you're bringing in parts temporarily for purposes like testing, demonstrations, or racing, you must secure written approval from the DOT/NHTSA before shipping the goods from the foreign country.

Adhering to these safety standards will help ensure a smoother customs clearance process.

4. File Importer Security Filing (ISF) for Ocean Shipments

If you're bringing in automotive parts by ocean, you'll need to submit an Importer Security Filing (ISF), also known as "10+2." This filing must be completed at least 24 hours before your cargo is loaded onto the vessel at the foreign port. Keep in mind, this requirement applies strictly to ocean shipments - not air, truck, or rail.

"The ISF is required to be submitted to US Customs and Border Protection no later than 24 hours prior to the cargo being loaded on the vessel destined to the United States." - Maersk

Failing to meet ISF requirements can lead to serious consequences. Late or incomplete filings might result in Do Not Load orders, cargo detention, or even seizure. U.S. Customs and Border Protection (CBP) has the authority to block your shipment from leaving the port or detain it upon arrival. Penalties are steep - up to $5,000 per violation and $10,000 per shipment. First-time offenders may face reduced fines, ranging from $1,000 to $2,000, while members of the C-TPAT program could see penalties reduced by as much as 50%.

Your ISF must include 10 key data points:

- Names and addresses of the seller and buyer

- Importer of record number

- Consignee number

- Manufacturer or supplier name and address

- Ship-to party details

- Country of origin

- HTS codes for each part

- Container stuffing location

- Consolidator information

It's important to be specific when describing your goods. Avoid vague terms like "auto parts" and instead use detailed descriptions, such as "ceramic brake pads" or "LED headlamp assemblies." This level of detail aligns with classification standards and ensures smoother processing. Also, remember that the country of origin refers to where the part underwent substantial transformation into its final form - not just where it was assembled.

Although the legal deadline for ISF submission is 24 hours before loading, it’s wise to file 2–4 days earlier. This extra time allows for document preparation and accounts for potential system delays. To avoid customs issues, ensure your ISF data matches the information on your Bill of Lading, commercial invoice, and packing list.

Most brokers charge between $30 and $50 for ISF filing. Additionally, you’ll need a customs bond in place. If you’re importing occasionally, a single-use bond (around $50–$100) may suffice. However, if you import regularly, a continuous bond might be a better option. Accurate and timely ISF filing, paired with thorough documentation, can help keep your shipments moving smoothly.

5. Prepare Complete Documentation Including Commercial Invoices and Packing Lists

Your commercial invoice and packing list are the backbone of any customs entry. U.S. Customs and Border Protection (CBP) relies on these documents to calculate duties, check compliance, and decide if your shipment needs inspection. Missing or incomplete paperwork can delay shipments until all the required details are submitted, causing unnecessary holdups. These documents set the stage for smooth customs clearance.

"The Commercial Invoice is required for all international commodity shipments and serves as the foundation for all other international shipping documents." - FedEx

Accuracy is key when preparing these documents. Your commercial invoice should clearly describe each automotive part. Use specific terms like "ceramic brake pads" instead of vague descriptions. Include essential details such as the Harmonized Tariff Schedule (HTS) code, unit value, total value, country of origin, and the manufacturer's full contact information. Even items provided for free, like samples, must be declared with their actual value to avoid incorrect duty calculations. Utilizing a bonded warehouse can help manage these costs by deferring payments until the goods are sold.

The packing list must align perfectly with the commercial invoice. It should detail the contents of each package, including quantities, net and gross weights (in both pounds and kilograms), and the country of origin. Any inconsistency between the commercial invoice, packing list, or bill of lading can raise red flags, leading to inspections or delays.

Be thorough. For instance, if you're shipping 10 sensors and 5 gaskets, list them separately with clear descriptions and values for each group - don’t combine them into a single entry. Additionally, make sure to include full contact information for both the sender and the consignee. Submitting your documents electronically can also speed up the review process, reducing the chances of delays.

6. Verify DOT Symbol and Compliance Labeling on Parts

For safety-related automotive parts, a permanent DOT symbol is essential. This marking confirms compliance with FMVSS regulations. Without it, customs officials may classify your shipment as "nonconforming", leading to potential holds, rejections, or expensive modifications through a Registered Importer.

"A DOT symbol inscribed on the item or its container usually indicates that the item is acceptable."

– Joe Weaver, USA Customs Clearance

The DOT marking must be permanently affixed to the part or its container. This requirement applies to various components, including tires, wheels, brake parts (pads, rotors, hoses), lighting systems (headlights, tail lights, bulbs), seat belt assemblies, automotive glass, and suspension parts like shock absorbers and ball joints. Ensure the marking is legible and matches the certification information provided on your DOT HS-7 form. These details are crucial for confirming compliance and avoiding unnecessary delays.

Missing or incorrect DOT labeling can lead to shipment holds, rejections, and costly modifications. As mentioned earlier, errors in classification or documentation have caused significant shipment delays. These delays often result in mounting storage and demurrage fees while issues are resolved.

To avoid these complications, conduct a thorough pre-export check. Verify that DOT symbols are visible, permanent, and that the parts meet the FMVSS standards in place at the time of manufacture. This proactive step ensures smoother customs clearance and helps safeguard your supply chain from disruptions.

7. Check Intellectual Property Rights Before Importing

Counterfeit or trademark-infringing automotive parts can create serious headaches. Beyond handling classification and documentation, you need to ensure your shipment doesn’t violate intellectual property (IP) laws. U.S. Customs and Border Protection (CBP) has the authority to seize any parts that infringe on patents, trademarks, or copyrights in the U.S.. If violations occur, you could face shipment seizures, hefty fines, personal penalties, and even increased customs scrutiny through frequent audits in the future.

The automotive parts market is massive - worth $422 billion annually - and ranks as the 9th most traded product category worldwide. This scale naturally attracts counterfeiters. To avoid falling into their trap, make sure your suppliers are legally certified to produce and export parts. Don’t take seller claims at face value; they can sometimes be misleading.

"Ensure the parts you're importing do not infringe on any U.S. patents, trademarks, or copyrights. This involves conducting thorough due diligence to verify the authenticity and legality of the automotive parts before importing them." – Dylan Sommer

Take extra precautions by obtaining detailed origin documentation from your suppliers. Train your team to carefully review key documents like the commercial invoice, packing list, and origin certificate before the shipment even reaches the border. Additionally, screen all business partners against the Denied Parties List to confirm they’re authorized to trade under U.S. Department of Commerce or Treasury regulations.

For components that carry a higher risk, it’s wise to consult a licensed customs broker or legal expert specializing in automotive logistics and IP law. Their expertise can safeguard your brand, prevent inventory losses due to confiscation, and help you avoid unnecessary financial setbacks. Taking these steps ensures your imports stay compliant and your customs process runs smoothly.

8. Use Bonded Warehouses to Defer Duty Payments

Customs bonded warehouses give you the option to store automotive parts without paying duties upfront. Instead of shelling out for duties right away, you can defer those payments until the parts actually enter the domestic market. This approach can significantly improve cash flow, especially when dealing with items that carry high tariffs.

"The most immediate benefit of using a bonded warehouse is financial, as shippers can postpone paying duties and taxes until goods leave the warehouse for onward travel." – Hannah Squire, Reload Logistics

Beyond the financial perks, bonded warehouses also provide operational flexibility. If market conditions change, you can re-export parts directly from the warehouse without ever paying U.S. duties. This setup is particularly useful for managing inventory in a fluctuating market. You can stockpile parts close to your target market and release them when the timing is ideal. This flexibility aligns well with efficient inventory management during customs clearance.

These warehouses operate under strict U.S. Customs and Border Protection (CBP) supervision, featuring 24/7 surveillance, controlled access, and meticulous record-keeping - essential safeguards for high-value automotive components. Many are strategically located near major ports or border crossings, making it easier to distribute parts quickly once they clear customs.

While the benefits for shipments with a standard 2.5% duty might be minor, the financial impact grows substantially for high-tariff items or large volumes. To maximize both financial and operational gains, choose a facility that is fully licensed, adheres to CBP regulations, and is located near key distribution hubs.

For added efficiency, consider partnering with a logistics provider like CR Express. Their CBW Class 3 solutions offer secure, GDP-compliant storage near major transportation hubs, ensuring smooth duty deferral and streamlined operations.

9. Calculate Duties, Taxes, and Fees Accurately

Getting your cost calculations right is a must if you want to avoid customs headaches and budget surprises. For most automotive parts, the standard duty rate is 2.5%. However, if you’re importing trucks, brace yourself for a steep 25% duty rate. Motorcycles are a bit of a mixed bag, with duties ranging from 2.4% to completely duty-free, depending on their origin.

Then there are additional tariffs that can complicate things further. Since May 3, 2025, a 25% ad valorem tariff applies to specific auto parts from all countries under Section 232. If you’re sourcing from China, tack on an extra 25% Section 301 tariff on top of the standard 2.5% rate. That means the total duty rate can soar to 27.5% or higher, so sourcing strategically is critical.

"Calculate the estimated duties, taxes, and fees associated with importing, and budget accordingly to avoid unexpected costs and delays." – Dylan Sommer, Clearit USA

Don’t forget to include Harbor Maintenance Fees (HMF) and Merchandise Processing Fees (MPF) in your calculations. These fees can quietly pile up and inflate your overall costs. Also, if your shipment is valued at $2,500 or more, you’ll need a customs bond, even if the parts themselves are duty-free. For nonconforming vehicles, be prepared for a DOT bond equal to 1.5 times the vehicle's dutiable value.

Stay on top of tariff changes by keeping an eye on Cargo Systems Messaging Service (CSMS) bulletins and using the ACE Secure Data Portal to audit your entries in real time. Since the de minimis exemption was suspended on August 29, 2025, every commercial shipment now requires either formal or informal entry processing. When it comes to more complex scenarios, like dealing with anti-dumping duties that can exceed 400% on components such as steel wheels or bearings, working with a licensed customs broker is a smart move. Accurate calculations are the backbone of a smooth customs clearance process.

10. Work with Logistics Providers for CFS Operations and Customs Support

Teaming up with a skilled logistics provider can be a game-changer for your customs clearance process. Beyond the compliance and documentation steps we've already discussed, an experienced partner can help you avoid costly errors and delays. For instance, misclassification issues have impacted thousands of shipments in the past, leading to fines and shipment holds. A knowledgeable provider ensures accurate HTS classification and proper COO documentation before your goods even leave the warehouse.

"In the world of automotive freight forwarding, precision is not a luxury. It's the price of entry." – Zarach Logistics

Container Freight Station (CFS) operations require meticulous coordination. Your logistics partner should oversee key tasks such as physical inspections, transloading goods from floor-loaded containers to pallets, and sorting items by purchase order, SKU, or part number for distribution to multiple destinations. This level of organization is especially crucial in the $159.6 billion U.S. automotive parts market. Providers with facilities near major ports can also help you sidestep detention and demurrage fees by ensuring containers are returned within the standard three-to-five-day window.

A capable provider will handle essential documentation and electronic filings like the Importer Security Filing (ISF) through the Automated Commercial Environment (ACE), which helps reduce the risk of fines or shipment delays. For shipments valued at $2,500 or more, they’ll secure the necessary customs bond and can arrange for bonded warehouse storage. This can be a major cost-saving measure, especially with the 25% Section 232 tariffs that came into effect on May 3, 2025. These services tie seamlessly into your broader customs clearance strategy.

When selecting a logistics provider, look for features like Transportation Worker Identity Cards (TWIC) for unrestricted port access and customs bonded warehouse (CBW Class 3) facilities, which allow you to defer duty and VAT payments until goods are released into domestic commerce. For example, CR Express operates a 280,000-square-foot bonded warehouse just five miles from Chicago O'Hare International Airport. Their location near major railyards and their privately owned chassis fleet help reduce drayage costs and keep containers moving smoothly.

Additionally, top-tier providers can guide you through duty relief programs like Inward and Outward Processing Relief and take advantage of preferential trade agreements such as USMCA to lower duty expenses. When dealing with high-stakes scenarios - like anti-dumping duties that can exceed 400% on components such as steel wheels or bearings - having a licensed customs broker in your corner is invaluable. Partnering with an expert logistics provider not only strengthens compliance but also streamlines operations for better overall efficiency.

Conclusion

Clearing customs for automotive parts doesn't have to be overwhelming if you focus on the basics. Success hinges on advance planning, accurate documentation, and understanding the requirements from agencies like CBP, EPA, and DOT. When you nail the details - like using the correct HTS codes, submitting proper compliance forms, and providing clear commercial invoices - you minimize the risk of delays and avoid costly fines.

With standard duties set at 2.5% for most parts and an additional 25% Section 232 tariff introduced on May 3, 2025, mistakes can quickly become expensive. Missteps like unclear product descriptions or errors in tariff classifications lead to delays, storage fees, and penalties, all of which eat into your bottom line.

This is where a dependable logistics partner proves invaluable. A company with customs bonded warehouse facilities (CBW Class 3) allows you to defer duty payments until goods enter domestic commerce, helping you manage cash flow during uncertain tariff periods. Ideally, your logistics partner should also handle CFS operations and maintain facilities near major ports and railyards to minimize detention and demurrage charges. For instance, CR Express operates a 280,000-square-foot bonded warehouse just five miles from Chicago O'Hare International Airport, with direct access to major railyards and a privately owned chassis fleet to keep shipments moving efficiently.

Partnering with a licensed customs broker is another smart move. They can help you handle complex scenarios, such as qualifying for preferential rates under USMCA. These experts review your HTS codes, verify country of origin documents, and ensure compliance with state-specific regulations like CARB standards. By aligning all aspects of your customs clearance process - from tariff codes to CFS operations - you strengthen your overall compliance strategy.

Attention to detail pays off. Whether you're importing engines, brake pads, or electronic control units, prioritizing customs clearance not only protects your business from unexpected costs but also ensures your parts reach the market without disruption.

FAQs

How can I confirm the right HTS code for a specific part?

To determine the correct HTS code for a part, review the Harmonized Tariff Schedule (HTS) and consult official resources or a trusted customs broker. Getting the classification right is crucial to prevent potential delays or penalties during customs clearance.

Which auto parts require EPA 3520-1 or DOT HS-7?

Automotive parts that include engines, such as replacement engines, require the EPA Form 3520-1 for importation. Similarly, some safety or compliance-related parts might necessitate the DOT HS-7 form, depending on their intended use. It's crucial to review the applicable regulations to ensure you're meeting all necessary requirements.

What’s the easiest way to reduce duties and avoid port delays?

To minimize duties and steer clear of port delays, it's crucial to classify and declare automotive parts accurately. Make sure to use the proper Harmonized Tariff Schedule (HTS) codes and submit clear, detailed paperwork. This reduces the risk of misclassification, which can trigger delays and extra duties.