Temperature-Controlled FTL vs. LTL Shipping

by CR Express Team, Logistics Team • 13 min read

Temperature-Controlled FTL vs. LTL Shipping

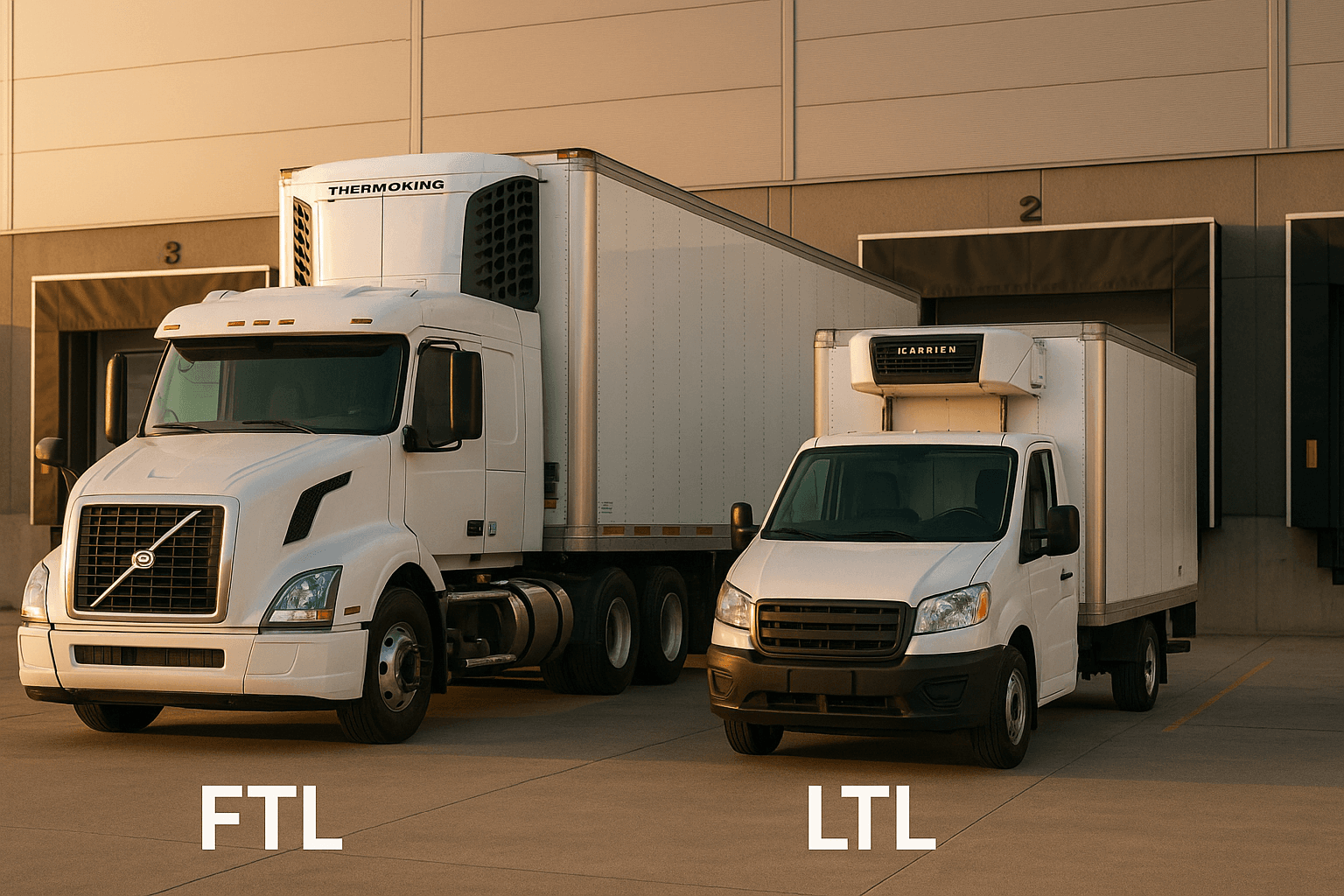

Temperature-controlled shipping protects sensitive goods like food and pharmaceuticals by maintaining specific temperature ranges during transit. Businesses typically choose between two options:

- FTL (Full Truckload): A dedicated truck for one shipment, offering faster delivery, minimal handling, and better temperature stability. Ideal for large, urgent, or high-value shipments.

- LTL (Less Than Truckload): Shared truck space for smaller shipments, making it more cost-effective but with longer transit times and higher handling risks. Best for smaller, regular shipments with flexible schedules.

Key Differences:

- FTL is faster and safer but more expensive for small loads.

- LTL is cheaper for small shipments but involves more stops and handling risks.

Quick Comparison:

| Factor | FTL | LTL |

|---|---|---|

| Cost | Higher for small loads, better for large shipments | Lower for small loads, less cost-efficient for large shipments |

| Transit Time | Faster, direct routes | Slower, multiple stops |

| Handling Risk | Minimal | Higher due to frequent transfers |

| Best For | Large, sensitive, or urgent shipments | Smaller, flexible shipments |

Choosing the right method depends on shipment size, urgency, and sensitivity. Providers like CR Express offer both options with GDP compliance, ensuring safe transport for temperature-sensitive goods.

LTL vs FTL Shipping Explained with Real Example | Full Truckload vs Less Than Truckload

What is Temperature-Controlled FTL Shipping

Temperature-controlled FTL (Full Truckload) shipping involves using an entire truck solely for one shipper's cargo, equipped with climate-control systems to maintain specific temperature ranges. Whether it’s keeping vaccines at 36–46°F or frozen goods at subzero temperatures, this method ensures precise climate management throughout the journey.

By dedicating the truck to a single shipment, the risk of contamination is minimized, as there’s no mixing of cargo. Additionally, the truck’s doors are typically opened only for loading and unloading, reducing exposure to external conditions. The shipment travels directly from the origin to its destination without intermediate stops, providing a streamlined and secure transport solution.

This approach is ideal for businesses handling large volumes of temperature-sensitive goods. For instance, a pharmaceutical company transporting 10 pallets of hazardous materials used FTL shipping to minimize handling risks and ensure compliance with strict regulations. The exclusive use of the truck also eliminates risks associated with temperature fluctuations caused by frequent door openings.

To support these needs, companies like CR Express offer temperature-controlled FTL services across 48 states. Their operations meet GDP (Good Distribution Practice) standards, utilizing validated cold chain logistics essential for industries like pharmaceuticals and healthcare.

Main Features of Temperature-Controlled FTL

Several key features make this shipping method reliable and efficient:

- Dedicated truck usage: The entire truck is reserved for one shipment, ensuring consistent temperature control and eliminating the risk of cross-contamination.

- Direct transit: Without additional pickups or drop-offs, shipments experience fewer temperature fluctuations. For example, a customer reduced delivery time from four days to just 1.5 days while maintaining temperature stability.

- Faster delivery: Direct routes enable quicker transit times. CR Express, for instance, leverages its proximity to O'Hare International Airport to offer same-day delivery within 200+ zip codes, ideal for urgent shipments.

- Reduced temperature risks: Limited handling and fewer door openings significantly lower the chances of temperature excursions, ensuring goods remain within their required ranges.

- Cost-efficiency for large loads: While upfront costs may be higher, FTL shipping can save money by reducing spoilage and avoiding regulatory penalties. A national paint manufacturer that switched from LTL (Less Than Truckload) to FTL in 2023 saw a 45% drop in freight claims due to better temperature management.

- Real-time tracking and monitoring: Modern FTL services include GPS tracking and digital monitoring systems. CR Express provides real-time updates on both location and temperature, giving shippers full visibility of their cargo.

When to Use Temperature-Controlled FTL

FTL shipping is particularly suited for specific scenarios:

- Bulk perishables: Items like fresh produce, meat, and dairy require consistent temperatures and protection from cross-contamination during transport to distribution centers.

- Pharmaceutical shipments: Vaccines, biologics, and specialty medications often require strict temperature control, such as 36–46°F. Direct transit with minimal handling ensures these critical ranges are maintained while adhering to FDA and GDP compliance standards.

- High-value temperature-sensitive goods: Products like specialty chemicals, biologics, or research materials justify the cost of dedicated shipping, as even minor temperature deviations can lead to significant financial losses.

- Hazardous materials: Certain substances, such as Class 3 liquids or Class 6 toxic materials, must travel alone per Department of Transportation regulations. Temperature control ensures their stability and safety during transit.

- Time-sensitive shipments: Seasonal produce, holiday food items, or urgent pharmaceutical supplies benefit from FTL’s direct routes, avoiding delays associated with LTL’s multiple stops.

- Regulatory compliance: Healthcare and pharmaceutical industries often require detailed temperature logs and chain-of-custody documentation. FTL’s streamlined logistics simplify compliance compared to the complexity of LTL shipping.

CR Express supports these industries with specialized handling protocols and rigorous regulatory adherence, ensuring products arrive intact and within required conditions from the manufacturer to the end user.

What is Temperature-Controlled LTL Shipping

Building on the concept of temperature-controlled FTL (Full Truckload), temperature-controlled LTL (Less Than Truckload) shipping offers a practical solution for smaller shipments that need climate control. This method involves sharing space in a refrigerated truck with shipments from multiple shippers, all while maintaining the required cold chain conditions throughout transit. Unlike FTL, where one customer utilizes the entire truck, LTL consolidates smaller loads into one trailer, making it a shared and more cost-effective option.

Temperature-controlled LTL typically handles shipments ranging from 150 to 15,000 pounds. The truck's refrigeration unit ensures that sensitive goods like frozen foods or pharmaceuticals stay within the required temperature range. However, because LTL involves multiple pickups and deliveries, transit times are longer, and there is more handling involved.

The process often includes cross-docking at distribution centers to consolidate shipments. For example, CR Express operates a cross-docking facility where goods from various shippers are combined and redistributed. Their fleet, equipped with refrigerated units, adheres to GDP compliance standards for pharmaceutical and healthcare logistics across the contiguous United States.

Temperature-controlled LTL stands out for its cost efficiency and scheduling flexibility, making it a go-to option for businesses with smaller, frequent shipments.

Main Features of Temperature-Controlled LTL

Several factors make temperature-controlled LTL shipping distinct:

- Cost Sharing: By combining shipments from multiple customers, freight costs can drop by up to 50% compared to FTL shipping.

- Higher Handling Risks: Because shipments pass through terminals and distribution centers for sorting and transfers, the risk of damage or loss is 2.5 times greater than with FTL.

- Longer Transit Times: Scheduled pickups, deliveries, and multiple stops can extend transit times, making LTL less suitable for urgent shipments but ideal for flexible distribution needs.

- Real-Time Tracking: Modern LTL providers offer digital tools that provide instant quotes, optimized carrier options, and continuous shipment tracking, ensuring transparency and visibility.

- Flexible Scheduling: Businesses can ship smaller quantities as needed while maintaining temperature control, making it a great option for frequent, low-volume shipments.

When to Use Temperature-Controlled LTL

Temperature-controlled LTL shipping works best when shipment size, frequency, and cost efficiency align. Here are some common scenarios:

- Small-Batch Frozen Foods: Specialty food distributors often use LTL to deliver smaller quantities of frozen products to restaurants or grocery stores. For instance, a gourmet ice cream producer might ship a few cases to various retail locations instead of waiting to fill an entire truck.

- Pharmaceuticals and Medical Supplies: LTL is ideal for distributing temperature-sensitive products like vaccines, lab specimens, or medical samples to clinics, pharmacies, or research facilities. The shared model helps reduce costs for smaller shipments.

- Specialty Beverages: Craft breweries or specialty drink manufacturers can use LTL to distribute refrigerated products to multiple retailers without the expense of FTL.

- Seasonal or Promotional Products: Companies launching limited-edition frozen items or holiday-specific goods can reach multiple locations simultaneously without needing a full truckload.

- Consistent Distribution Networks: Businesses that regularly ship smaller volumes to the same destinations benefit from LTL's predictable scheduling and cost savings. While the increased handling risk may not suit fragile goods, it works well for less delicate items.

Industries like food and beverage, healthcare, pharmaceuticals, and specialty chemicals often rely on temperature-controlled LTL shipping to balance cold chain requirements with cost-effective transportation for mid-sized shipments.

sbb-itb-c0b8770

Temperature-Controlled FTL vs LTL Shipping Comparison

Understanding the differences between temperature-controlled FTL (Full Truckload) and LTL (Less Than Truckload) shipping is essential for businesses managing cold chain logistics. Each option is suited to specific needs based on shipment size, urgency, and budget. Below, we break down key distinctions in cost, transit time, and scheduling to help you decide which method fits your requirements.

Cost and Efficiency Differences

With temperature-controlled FTL shipping, you pay for the entire truck, whether it’s fully loaded or not. This makes FTL a better choice for large shipments that fill most of the trailer. On the other hand, LTL shipping allows you to share space - and costs - with other shippers, making it a more economical option for smaller loads.

Efficiency also varies between the two. FTL shipments are loaded once at the origin and delivered directly to the destination, minimizing handling and reducing the risk of temperature fluctuations. In contrast, LTL shipments involve multiple stops and transfers at distribution centers, which can complicate operations and increase the potential for temperature inconsistencies.

Transit Time and Risk Differences

Transit time is critical for temperature-sensitive goods. FTL shipping offers faster, more predictable delivery due to its direct routing. LTL shipments, however, take longer because of multiple stops and transfers, which can also increase the risk of temperature deviations and physical damage.

For example, a case study involving refrigerated Class 6.1 pesticides revealed that switching from LTL to FTL reduced delivery times from 4 days to just 1.5 days. Additionally, the risk of loss or damage in LTL shipping is up to 2.5 times higher than in FTL, largely due to the increased handling and transfers involved.

Flexibility and Scheduling Differences

FTL shipping provides greater control over pickup and delivery times, which is particularly important for businesses with strict deadlines or specific receiving windows. However, FTL services may not run as frequently, especially when specialized temperature-controlled equipment is required.

LTL services, on the other hand, offer more frequent departures, making them a flexible option for businesses shipping smaller quantities regularly. The downside is less control over delivery timing, as LTL schedules are designed to consolidate shipments from multiple shippers. For instance, a pharmaceutical company shipping Class 6 toxic substances chose FTL to ensure precise scheduling and reduce handling risks.

| Comparison Factor | Temperature-Controlled FTL | Temperature-Controlled LTL |

|---|---|---|

| Cost | Higher total cost for smaller loads; lower per-unit cost when fully utilized | Lower total cost for smaller loads; cost benefits decline with larger shipments |

| Efficiency | Direct service with minimal handling | Multiple stops and transfers increase complexity |

| Transit Time | Faster and more predictable | Longer and less consistent |

| Risk | Lower risk due to minimal handling and stable temperature | Higher risk of damage or loss due to frequent handling |

| Temperature Control | More stable with fewer fluctuations | Greater exposure to temperature changes |

| Scheduling | Greater control over timing | Less control, as schedules depend on shipment consolidation |

| Departure Frequency | Less frequent availability | More frequent services |

| Best For | Large, urgent, or highly sensitive shipments | Smaller, cost-sensitive shipments shipped regularly |

Choosing between FTL and LTL shipping comes down to balancing cost, speed, and risk, as well as your operational priorities. Providers like CR Express offer both options, equipped with specialized tools and GDP compliance, to help businesses tailor their cold chain logistics to their unique needs and shipment characteristics.

How to Choose the Right Temperature-Controlled Shipping Option

When deciding between temperature-controlled FTL (Full Truckload) and LTL (Less Than Truckload) shipping, it’s essential to weigh factors like shipment size, sensitivity, delivery speed, budget, and compliance needs. Each option offers unique advantages depending on your specific requirements.

Start by considering shipment size and weight. If your shipment is close to 20 pallets or exceeds 15,000 lbs, FTL is often the better choice since it maximizes trailer space and can be more economical for large loads. On the other hand, smaller shipments - typically between 150 and 15,000 lbs - are well-suited for LTL. With LTL, you share truck space with other shippers, which helps cut costs and eliminates the need to wait for a full truckload.

Next, think about the sensitivity and value of your goods. Products that are fragile, time-sensitive, or high-value often benefit from FTL shipping. FTL minimizes handling, offers direct delivery, and provides greater control over pickup and delivery schedules, making it ideal for businesses with tight deadlines. LTL, however, is a good fit for smaller, regular shipments where timing is flexible. Regulatory compliance is another key consideration. For example, hazardous or heavily regulated goods often require FTL to ensure proper handling and avoid potential compatibility issues with other cargo. A pharmaceutical company, for instance, opted for FTL to transport 10 pallets of Class 6 toxic substances (under 5,000 lbs), reducing handling risks and meeting strict regulatory standards.

You should also factor in long-term costs. While LTL may seem cheaper upfront for smaller shipments, the risk of delays or damage could offset those savings. Take the case of a national paint manufacturer shipping hazardous Class 3 liquids: repeated compliance delays and freight rejections with LTL led to costly disruptions. By switching to FTL, they cut freight claims by 45% and improved customer satisfaction. In such scenarios, the overall cost of ownership - including risk reduction - can make FTL’s higher initial cost worthwhile.

CR Express specializes in helping businesses navigate these decisions. Their logistics experts assess shipment profiles, product sensitivity, delivery timelines, and budgets to recommend the best temperature-controlled shipping solution. As a GDP-compliant carrier, CR Express offers both FTL and LTL services, complete with real-time tracking, regulatory expertise, and tailored logistics plans to ensure safe and efficient transport across all 48 states.

Ultimately, choosing the right option requires a careful analysis of your shipment patterns, total cost of ownership, and acceptable risk levels to align with your operational goals.

Final Thoughts on Temperature-Controlled Shipping

Temperature-controlled shipping requires a careful balance between cost, risk, and operational demands. Full Truckload (FTL) shipping stands out for its dedicated service, minimal handling, and faster transit times, making it ideal for high-value, sensitive, or time-critical shipments. On the other hand, Less Than Truckload (LTL) shipping offers a more economical solution for smaller loads. However, increased handling in LTL can pose up to 2.5 times greater risk to shipments.

These operational differences can significantly affect financial performance. For example, businesses that switch from LTL to FTL for sensitive goods have reported freight claims dropping by as much as 45%, while delivery times have been slashed by over 50% - from 4 days to just 1.5 days. The reliability and speed of FTL often outweigh its higher upfront costs when considering the broader picture of ownership expenses. This highlights the critical role of a strong cold chain logistics system.

The choice between FTL and LTL should be guided by the sensitivity of your products and the regulatory environment. Pharmaceuticals, vaccines, and other temperature-sensitive items usually demand FTL's controlled environment and direct routing to ensure product integrity and compliance with stringent industry standards. For less sensitive goods or smaller, regular shipments where timing is less critical, LTL’s shared-cost model can offer significant savings without sacrificing quality. These considerations emphasize the importance of working with an experienced logistics provider.

With 26 years of expertise, CR Express delivers GDP-compliant, temperature-controlled shipping solutions. Their capabilities include both FTL and LTL services, supported by real-time GPS tracking and validated cold chain processes. Their asset-based fleet features specialized reefer equipment to maintain consistent temperature control, regardless of shipment size.

When deciding on a shipping method, consider factors like shipment frequency, product value, regulatory requirements, and acceptable risk levels. By choosing the right logistics partner and shipping approach, you can protect product integrity, manage costs efficiently, and create a supply chain that drives long-term growth and customer satisfaction. The key is aligning your shipping strategy with your specific needs to ensure reliability, cost control, and a sustainable supply chain.

FAQs

What factors should I consider when choosing between temperature-controlled FTL and LTL shipping?

When choosing between temperature-controlled Full Truckload (FTL) and Less-than-Truckload (LTL) shipping, you’ll need to weigh factors like shipment size, timing, and budget.

FTL works best for larger shipments that fill an entire truck and need quicker delivery times. On the other hand, LTL is a more budget-friendly option for smaller shipments, as your goods share space with other cargo. Both options can handle temperature-sensitive shipments, but FTL often provides more control and efficiency for delicate or perishable items.

Think about what matters most for your business - whether it’s saving on costs, meeting tight delivery deadlines, or ensuring the safety of temperature-sensitive goods - to decide which option suits your needs.

What are the risks of temperature-controlled LTL shipping, and how can they be managed?

Temperature-controlled less-than-truckload (LTL) shipping has its challenges, especially when it comes to keeping temperatures steady throughout the journey. Because LTL shipments share truck space with other goods and involve multiple stops for loading and unloading, the risk of temperature fluctuations increases.

To reduce these risks, partnering with a dependable logistics provider experienced in temperature-controlled shipping is key. Look for carriers that use advanced refrigeration systems and offer real-time temperature monitoring. Proper packaging and insulation also play a big role in protecting your goods during transit. Finally, make sure to clearly communicate your specific temperature requirements to your logistics provider to ensure everything arrives safely.

Why would a business invest in temperature-controlled FTL shipping despite its higher cost?

Temperature-controlled full truckload (FTL) shipping can be a smart choice for businesses that need to protect sensitive goods during transit. With FTL, the entire truck is reserved for your shipment, allowing for precise temperature control throughout the trip. This significantly reduces the chances of spoilage or damage, making it ideal for transporting perishable items like food, pharmaceuticals, or other goods that require specific temperature conditions.

FTL shipping also offers quicker transit times. Since the truck moves directly from the pickup point to the delivery destination without making multiple stops, it ensures faster and more reliable delivery. For businesses focused on maintaining product quality and meeting tight schedules, this level of efficiency is often worth the higher cost. While it may involve a larger upfront expense, the peace of mind and protection it provides for valuable shipments can make it a worthwhile investment in the long run.